Rice flour is a finely milled powder made from rice grains. It is widely used in the food industry due to its gluten-free nature and neutral flavour. Rice flours versatility makes it a popular alternative to wheat flour, as it meets the need of gluten-free, and allergen-free formulation across food, cosmetics, and agricultural industries.

This article explores the different types of rice flours, market trends, supply chain, and functional benefits in large-scale production, enabling manufacturers to maximise its potential across various products.

Types of Rice Flour and their Applications in Formulations

Each type of rice flour offers unique functional benefits, allowing it to be suitable for different manufacturing needs.

White Rice Flour – Made from polished white rice, white rice flour is light and neutral in flavour. It possesses a fine texture which makes it a popular base for gluten-free formulations such as bread, pastries, snacks, and powdered mixes (Celiac Disease Foundation).

Brown Rice Flour – Retaining its bran layer, brown rice flour adds fibre and nutrients to formulations, giving them a nutty taste and dense texture. It is commonly used in healthy food products, including nutrition bars, wholegrain baked goods, and fibre-enriched snacks.

Glutinous (Sticky) Rice Flour – Known for its adhesive properties, glutinous rice flour is a great option for formulations within the food industry. It is often used in confectionary products, dumplings, mochi, rice cakes, and applications that require binding, texture cohesion, and stabilisation (Institute of Food Technologists).

Generally, rice flour is milled from broken rice, but it can also be produced from whole rice. Milling from whole rice, however, is typically more expensive due to its value and use by the general consumer in supermarkets.

What are the Nutritional Benefits of Rice Flour?

Rice flour possesses a variety of nutritional benefits…

Digestive Health – Rich in fibre, especially in brown rice flour, it helps with constipation and promotes healthy digestion.

Cardiovascular – With its antioxidant properties, rice flour helps control cholesterol and prevent cardiovascular diseases.

Bone Health – Rich in phosphorus and magnesium, rice flour contributes to the absorption of vitamin D and the maintenance of bone health.

Weight Control – Fibre increases the feeling of satiety, helping with weight loss and hunger control throughout the day.

Energy – With carbohydrates, proteins, zinc, and magnesium, rice flour provides energy, as well as muscle recovery and an increase in strength and endurance.

What is the Market Demand for Rice Flour?

As consumer interest in wellness continues to increase, so does the demand for allergen-free, and clean-label foods, like rice flour. This ingredient appeals to a wide range of consumers, especially those that possess gluten sensitivities and celiac disease (Mintel). Manufacturers are looking to increasingly incorporate rice flour into their formulations for products such as protein supplements, fibre-enriched snacks, and gluten-free pasta, aligning with ever increasing popularity of healthy food products (Euromonitor International).

Rice flour’s applications in food products include:

- Gluten-free baking (cookies, cakes, muffins, etc.)

- Soups, sauces, as well as other dishes that require a smooth consistency

- Gluten-free pancakes and crepes

- Veggie burgers and meatballs

- Baby food

Rice flour can also be used in animal feed. It is a gluten-free option that improvises palatability, binds feed particles together, and provides essential nutrients, like proteins and vitamins. As well as being easily digestible, ensuring efficient absorption of nutrients and minimises digestive problems.

What are the Functional Properties of Rice Flour in Food Manufacturing?

Rice Flour possesses many functional properties, allowing manufactures to achieve specific sensory and nutritional outcomes.

Thickening and Stabilising

Rice flour is a reliable thickening agent in a wide variety of soups, sauces, and gravies, and even remains stable when refrigerated, or frozen. This strong stability makes rice flour ideal for shelf-stable sauces and processed dairy products (Celiac Disease Foundation).

Binding and Texturising

In gluten-free baking, rice flour provides the necessary structure, while glutinous rice flour serves as a strong binding agent, enhancing the chewiness and texture cohesion of a product. This functionality makes rice flour a valuable ingredient in products like pastries, fillings, and extruded snacks (Institute of Food Technologists).

Extrusion and Crisping

For extruded snacks, rice flour contributes to crispiness and lightness of products, making it ideal for chips, crackers, and rice cakes. It also works well as a coating for fried foods, providing items such as tempura, breaded fish, and vegetable snacks a light, and crispy texture (American Association of Cereal Chemists).

What are the Non-Food Applications of Rice Flour in Manufacturing?

Beyond its applications within food production, rice flour has industrial applications that highlight its adaptability through different industries.

Cosmetic Industry

Rice flour is a valued ingredient in cosmetics due to its natural exfoliating properties, making it suitable for face masks and scrubs. It also serves as a natural, plant-based alternative to talcum in powder formulations, catering to the growing clean-beauty trend (American Academy of Dermatology).

Agricultural Applications

In sustainable agriculture, rice flour can be mixed with vermiculite as a substrate for mushroom cultivation. It possesses organic and absorbent properties which make it useful in soil conditioning and organic pest control (Mushroom Growers’ Association).

The Rice Flour Market and Supply Chain Considerations

The global rice flour market has seen significant growth due to the increased demand for gluten-free and clean-label products. As consumers are beginning to prioritise allergen-free and health-oriented foods, rice flour has become a staple in various food formulations.

Major Producers

Asia is the dominant leader in global rice production, with China and India producing half of the worlds rice supply. Other significant producers of rice include Indonesia, Bangladesh and Vietnam, as well as European countries such as Italy, Spain, and Portugal. These countries help support a robust rice flour supply chain essential for meeting worldwide demand (Food and Agriculture Organization).

Market Growth

In 2022, the global rice flour market was valued at around $1.1 billion, with projections suggesting it will reach around $1.65 billion by 2030 (The Insight Partners). This growth of the rice flour market reflects the increasing adoption, and embrace of gluten-free products, with rice flour serving as a key component to gluten-free products, due to it being a great alternative to wheat flour within these formulations.

Supply Chain Considerations

The supply chain for rice flour involves multiple stages:

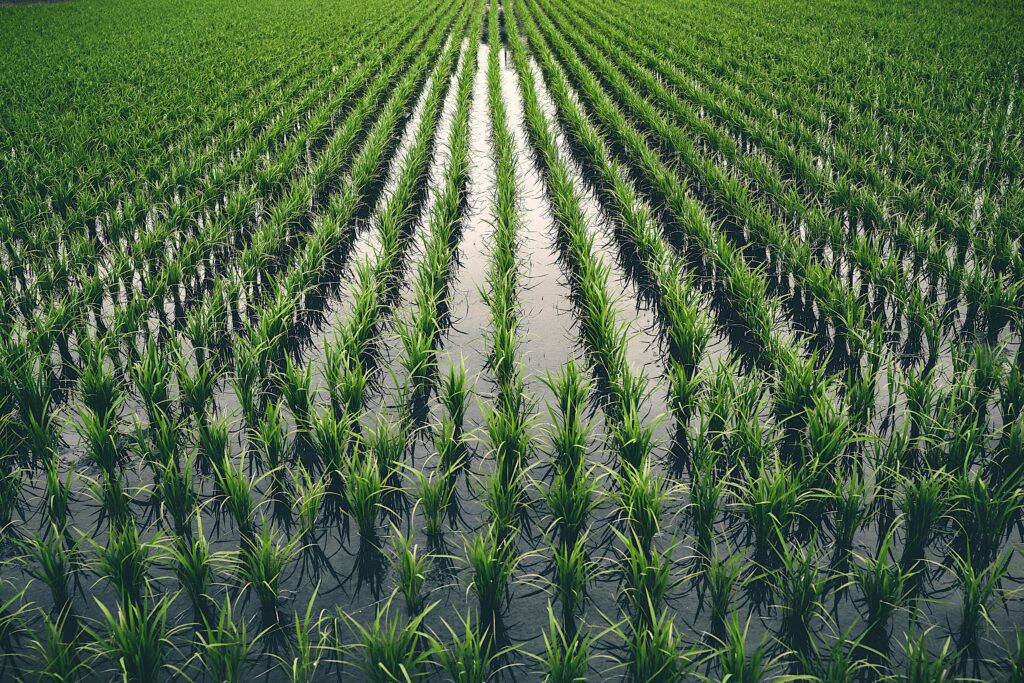

- Cultivation – Rice cultivation begins with preparing the fields, which are often flooded to create paddies. This helps control weeds and pests while maintaining the right conditions for growth. Seeds, or seedlings, are then planted, typically in rows to ensure proper spacing. As the plants grow, they require consistent water levels and careful management to prevent diseases. Once the grains mature and turn golden, the crop is harvested.

- Harvesting and Milling – Rice grains are harvested and then milled to remove their husk. It is then polished to produce white rice flour, whilst brown rice flour retains its bran.

- Processing and Packaging – The rice is then ground into a fine powder under controlled conditions, in order to ensure a consistent quality.

- Distribution – The packaged rice flour is then distributed globally through wholesalers, speciality stores, and online retailers.

Potential disruptions within the rice flour supply chain, such as climate effects on crop yield and logistical challenges, can significantly impact its availability and cost. Climate change, in particular, poses a serious threat. Drought, for example, is a growing concern as rice cultivation requires a lot of water. Prolonged periods of low rainfall or water shortages in key growing regions can severely affect crop yields, leading to reduced supply and increased prices, an issue that has been faced in many regions in the world.

How Rice Flour is Produced at Scale

Producing rice flour for industrial use requires specialised milling and processing to ensure its consistency, texture, and safety.

Industrial Milling Process

Rice flour production begins with milling. This is where grains (predominantly broken) are stripped of their outer husk. As mentioned above, for white rice flour, the rice is polished to remove the bran layer, whilst brown rice flour retains it, providing fibre and nutrients. High-speed industrial grinders ensure that the rice flour possesses a consistent particle size, a key factor for product uniformity in manufacturing (Food and Agriculture Organization).

Grinding and Quality Control

After milling, the rice is then ground into a fine powder. Quality control measures, such as sieving, are then applied to remove any impurities within the flour, while moisture control preserves the its shelf life and functional properties (American Association of Cereal Chemists).

Packaging and Storage

Rice flour is sensitive to humidity, so it should be stored in airtight, food-safe containers. For bulk storage, silos and large containers help maintain quality by keeping the flour cool and dry, preventing clumping.

Frequently Asked Questions (FAQs)

How does rice flour differ by country of origin?

The quality and texture of rice flour can vary based on origin due to a multitude of factors, including rice variety and milling techniques. Japanese rice flour, for example, is usually fine and suited for delicate confections, while South Asian rice flour has a denser texture for heartier dishes (Food and Agriculture Organization).

Can rice flour be used in non-gluten-free formulation?

Yes! Rice flour can be used to enhance texture, binding, and crispiness even in products containing gluten, thanks to its natural flavour and versatile application in snacks and baked goods.

What storage conditions are optimal for rice flour?

Rice flour should be stored in a cool, dry place to maintain quality, using airtight containers or silos for bulk storage prevent moisture absorption and the flour from clumping.

Is ground rice the same as rice flour?

No, ground rice has a coarser texture, while rice flour is finely milled into a smooth powder. In food manufacturing, the fine texture of rice flour is essential for providing consistency throughout doughs, batter, and sauces, whereas the coarse granules in ground rice make it less suitable for products requiring a refined texture.

Can you make rice flour from any type of rice?

Yes, white, brown, and glutinous rice can all be used, each lending different textures to recipes:

- White Rice Flour: Smooth and neutral, ideal for light, crispy snacks and baked goods.

- Brown Rice Flour: High in fibre an nutrients, providing a wholesome element to formulations.

- Glutinous Rice Flour: Known for its sticky quality, it provides elasticity, especially when used in chewy confectionaries and fillings.

Can you make rice flour at home?

Yes, rice flour can be made at home using a high-speed blender, or grain mill. Here is a quick DIY guide:

- Choose the Rice Type: Depending on the desired texture and nutritional content, select white, brown, or sticky rice.

- Rinse and Dry: Rinse the rice and dry it thoroughly to avoid clumping.

- Blend or Grind: Use a high-speed blender or grain mill to grind the rice in small batches until it reaches a fine powder consistency.

- Sift: Sift the flour to remove larger particles, ensuring a smooth and even texture.

Is rice flour healthier than corn starch?

Rice flour offers a healthier profile than corn starch in some ways. While they both are gluten-free, rice flour contains more fibre, especially brown rice flour, which support digestive health and satiety. Additionally, rice flour tends to be higher in protein, and lower in fat, making it more suitable for formulations that are aimed at heart health or weight management.

Conclusion

The versatility that rice flour possesses makes it a valuable ingredient for food manufacturers and product developers across a variety of industries. With its gluten-free nature, nutritional benefits, and capacity to function as a thickener, binder, or texturiser, rice flour has applications that go far beyond traditional food products. In manufacturing, rice flour supports diverse gluten-free foods, fibre-enriched products, and even non-food applications, like cosmetics and agricultural products. For those looking to innovate or diversify their formulation, rice flour offers a promising option. Its adaptability allows manufacturers to meet the ever-growing demands of health-conscious consumers that are seeking allergen-free, clean label food products. By exploring rice flour’s potential uses, food industry professionals can enhance products quality and respond to the evolving market trends with a versatile, functional, and sustainable ingredient.

Lehmann Ingredients have a 35 year history in the sourcing and supply of food ingredients for customers both in and outside of the UK. We are trusted suppliers of high-quality Rice Flour products to a number of high-profile organisations from start-ups to more established food companies leading in various retail categories.

We source our Rice Flour from Qualiriso. Qualiriso manufacture in Europe (Portugal) and their focus upon quality fits perfectly with our own objectives to ensure that we meet strict targets in quality, volume and price. So whether you have a specific challenge to reformulation, or a custom idea for NPD, then do reach out.

Contact a member of our team by emailing enquiries@lehmanningredients.co.uk or calling +44 (0) 1524 581560.