The Sweet Spot of Innovation

Confectionery manufacturing is where science meets storytelling – blending heritage techniques with modern-day expectations for taste, texture, and transparency. From chewy sweets and aerated nougat to rich fudges and fruity jellies, the category is more dynamic than ever.

However, today’s consumers crave more than just sweetness – some still reach for that old school chocolate hit. Others want indulgence that goes beyond, aligning with modern values : less sugar, cleaner labels, natural ingredients, and no compromises.

At the heart of this evolution lies one key ingredient: sugar. But not all sugars are created equal. Whether it’s sucrose, glucose, or fructose, each sweetener brings a different profile of sweetness, solubility, texture, preservation, and processing behaviour. Understanding how these sugars interact in confectionery is essential for formulators looking to balance flavour, stability, and shelf life.

This article explores:

- How different sugars behave in confectionery systems

- Why sweetener choice affects more than just taste

- How confectionary is made, and the equipment and machinery involved

- How clean label and sugar-reduction trends are shaping the future of confectionery innovation

At Lehmann Ingredients, we help manufacturers navigate this complex landscape with a wide portfolio of sweeteners, starches and functional ingredients to help solve all manner of formulation challenge.

Overview of Confectionery Categories

The world of confectionery is remarkably diverse, encompassing a wide range of textures, flavour profiles, and processing requirements. For manufacturers, each product category presents unique challenges – and opportunities – for innovation through ingredient selection and formulation.

1.Sugar Confectionery

This includes traditional favourites like hard candy, gummies, toffees, jellies, and boiled sweets. These products rely heavily on sugar’s ability to crystallise (or not), depending on the desired texture. Sucrose provides structure and crunch in hard candies, while glucose syrups and invert sugars are essential in preventing crystallisation and delivering a soft, chewy bite in products like gummies and jellies.

2.Chocolate and Compound Coatings

From premium truffles to everyday coated snacks, chocolate manufacturing is both art and science. Sugar not only sweetens but also impacts mouthfeel, bloom resistance, and shelf stability. Compound coatings – often used as cost-effective alternatives – depend on precise emulsifier and sweetener ratios to mimic the sensory appeal of real chocolate.

3.Chewing Gum and Bubble Gum

This specialist category depends on a gum base for elasticity, combined with sweeteners like glucose or sorbitol for sustained flavour release and chew quality. Moisture control and anti-crystallisation are crucial to maintaining softness over time.

4.Aerated Products

Nougat, marshmallow, and aerated bars rely on foaming and stabilising agents, combined with sugars that deliver structure without crystallising too quickly. Sucrose and glucose syrups are commonly used, and timing of aeration plays a key role in achieving the right bite and resilience.

Sweeteners Used in Confectionery

In confectionery manufacturing, a broad spectrum of sweetening agents is used – each with distinctive functional, sensory, and label‐friendly attributes. Below is a list of commonly deployed sweeteners and key considerations when applying them:

- Granulated Sugar (Sucrose): The classic benchmark sugar that provides bulk, structure, and clean sweetness; often used in hard candies, brittles and fondants.

- Brown Sugar: Similar to sucrose but with added molasses content, influencing colour, flavour note (caramel/rum-like) and moisture retention.

- Confectioner’s (Icing) Sugar: Finely milled sugar with anti‑caking agents; used for dips, coatings, glazes, and powders on sweets.

- Invert Sugar: A blend of glucose and fructose created by hydrolysis of sucrose. Offers softer texture, improved moisture retention and anti‑crystallisation for filled chocolates or gummies.

- High‑Fructose Corn Syrup (HFCS): Widely used in some markets, especially for cost and processing advantages, though often avoided in UK/EU due to GMO origin concerns and consumer perception.

- Fructose: A monosaccharide, sweeter than sucrose. Useful where sweetness must be increased or total sugar reduced while maintaining chew and moisture.

- Oat Syrup provides a mild, rounded sweetness with good binding and moisture-retention properties, making it well suited to bars, fillings, and clean-label confectionery where a softer texture and natural positioning are important.

- Rice Syrup delivers gentle sweetness and anti-crystallisation benefits, helping control texture and stability in confectionery applications such as caramels, chews, and coatings, particularly where fructose-free formulations are required.

- Glucose / Dextrose: Monosaccharide with milder sweetness; in syrup form offers smooth mouthfeel, low crystallisation risk and aids browning (Maillard reaction).

- Glucose syrup is a really important one for confectionary and moderately sweet with a DE of 42.

- Honey / Maple Sugar / Agave Syrup: Natural/“artisan” sweeteners with cleaner‑label appeal; contribute sweetness, flavour character and marketing differentiation, though often raise cost or change process behaviour.

- Sugar Alcohols (Polyols) – Xylitol, Erythritol, Mannitol, Isomalt, Maltitol : Lower‑calorie alternatives with sweet‑and‑bulking functionality; commonly used in “sugar‑free” or diabetic‑friendly confectionery, in fact Maltitol can replace sugar 1:1 though require awareness of digestive tolerance, and too much can have a laxative effect.

- High‑Intensity Sweeteners – Sucralose, Acesulfame‑K, Aspartame, Saccharin, Neotame, Thaumatin, Steviol Glycosides (Stevia): Ultra‑sweet compounds used to reduce sugar content significantly. They require bulking or texturising systems to replace bulk of sugar and must meet regulatory and labelling mandates.

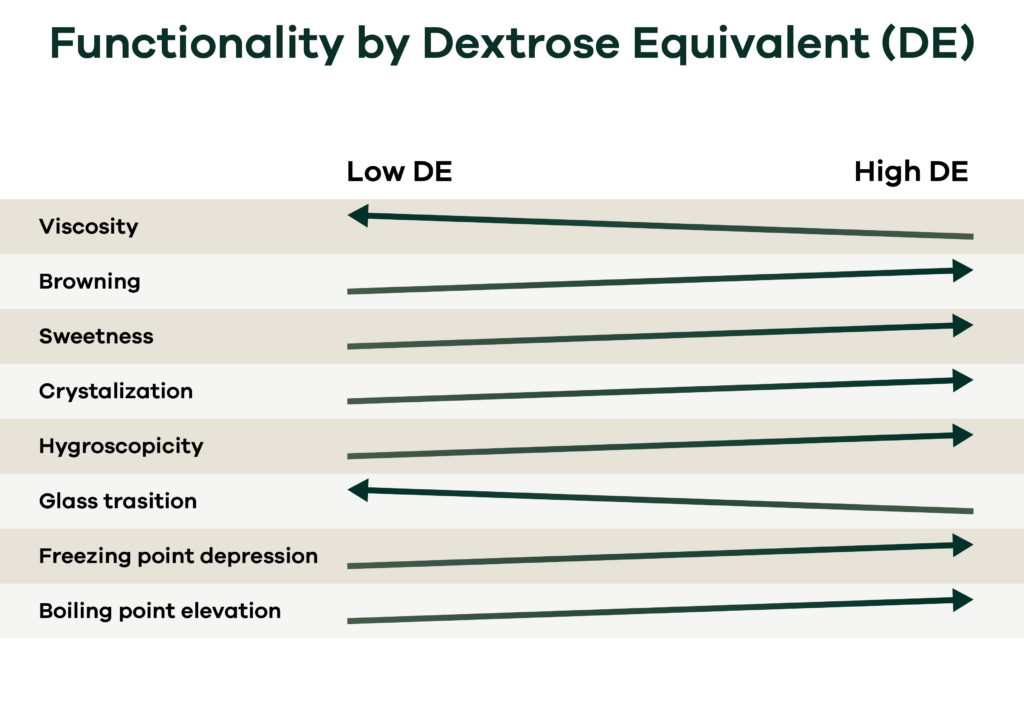

Each sweetener is considered not only for its “sweetening power” but also its impact on texture, stability, crystallisation, mouthfeel, cost, processing behaviour and label positioning. The reason why so many of these work is because of the DE (dextrose equivalent). The molecular make up of a lot of these syrups and sweeteners is actually quite similar, and offering comparable function, despite coming from different sources. Although there are also some nuances and benefits to some over others.

Regulatory approvals (such as those by the European Food Safety Authority [EFSA] for specific sweeteners) impose usage limits and labelling requirements.

When choosing a sweetener system for confectionery, manufacturers must ask:

- Does it give the right texture, chew, snap or softness?

- Will it behave under my process conditions (heat, shear, cooling)?

- Does it support my label claims (e.g., “no added sugar”, “clean label”, “natural”)?

- How will it affect shelf stability, moisture migration and crystallisation?

By mapping functional sweeteners to product objective, manufacturers can create indulgent treats that meet modern expectations – from flavour and texture to label clarity and processing efficiency.

Key Functions of Sugars in Confectionery

Sugars and sweeteners used in confectionery don’t just deliver sweetness – they shape the product’s structure, texture, mouthfeel, and even shelf-life. Whether you’re formulating a chewy fruit bar, a crunchy brittle, or a soft fondant, the type of sweetener chosen directly influences the final product’s performance and appeal.

Sweetness Delivery and Scale

Not all sweeteners deliver the same level of intensity. The sweetness scale, measured relative to sucrose (which is benchmarked at 1.0), helps formulators predict and manage the perceived sweetness of different ingredients.

Each sweetener brings a different intensity and sweetness curve:

- Fructose, sucralose, and steviol glycosides (stevia) offer high sweetness intensity – ideal for reduced-sugar formulations where you need to do more with less.

- Granulated sugar (sucrose) and invert sugar provide clean, familiar sweetness with a balanced onset and dissipation.

- Maltitol, erythritol, xylitol, and mannitol are polyols offering low-calorie sweetness with minimal glycaemic impact, often used in “no sugar added” or diabetic-friendly confectionery.

- Sweeteners like aspartame, neotame, and acesulfame potassium are intensely sweet and effective at very low concentrations, useful in sugar-free gum and lozenges.

| Sweetener | Relative Sweetness (vs Sucrose) |

|---|---|

| Sucrose (table sugar) | 1.0 |

| Glucose (dextrose) | 0.6–0.8 |

| Oat Syrup | 1-1.24 |

| Rice Syrup | 0.6-0.8 |

| Fructose (crystalline) | 1.2–1.8 |

| Invert sugar | 1.1–1.3 |

| High-fructose corn syrup (HFCS-55) | ~1.0 |

| Honey | 1.2–1.5 |

| Stevia (steviol glycosides) | 150–300 |

| Sucralose | 600 |

| Aspartame | 180–200 |

| Acesulfame-K | 200 |

| Saccharin | 300–400 |

| Xylitol | 1.0 |

| Erythritol | 0.6–0.7 |

| Maltitol | 0.9 |

| Neotame | ~7,000–13,000 |

| Thaumatin | ~2,000–3,000 |

Why it matters:

- Choosing a high-intensity sweetener (like sucralose or stevia) allows for sugar reduction, but may require bulking agents to replicate mouthfeel.

- Polyols (e.g., maltitol, xylitol, erythritol) offer lower glycaemic impact and are useful in sugar-free confectionery.

- Natural options like agave bring added flavour and label appeal but impact formulation differently.

Texture Creation

Sugars are structural components:

- Sucrose contributes to brittleness in hard candy and crystallisation in fondants and fudge.

- Glucose syrup and invert sugars inhibit crystallisation—ideal for chewy confections like caramels or nougat.

- Maltitol, xylitol and mannitol can create a cooling effect and crunchy texture, especially in chewing gum.

- Agave offers viscosity and flexibility, supporting moist textures in cereal bars and soft-centred confections.

Maillard Reaction Potential

Sugars like glucose, fructose, dextrose, and maltose are reducing sugars, which actively participate in Maillard browning—essential for caramel flavours, baked colour, and roasted notes in cereal bars and toasted toppings.

Sucrose, being a non-reducing disaccharide, requires inversion to contribute to these reactions.

Polyols like erythritol have little Maillard reactivity, which can be advantageous when browning is not desired.

Mouthfeel and Bulk

Sweeteners often provide critical volume and texture:

Stevia, sucralose, and acesulfame K need bulking agents (like maltodextrin or inulin) to maintain proper volume and mouthfeel in reformulated products.

Invert sugar and glucose syrup lend smoothness and prevent gritty textures.

Oat syrup and rice syrup are increasingly used in confectionery as functional, label-friendly alternatives to traditional sugars. Both provide gentle sweetness alongside essential bulk, viscosity, and binding, helping maintain structure and mouthfeel in reduced-sugar or clean-label formulations.

Sucrose, brown sugar, and confectioners’ sugar add body, bulk, and density to everything from marshmallows to buttercream.

Preservation

Sugars help stabilise products by lowering water activity:

- Fructose and glucose syrups are highly hygroscopic—ideal for chewy bars and gummies that must remain moist and pliable.

- Sucrose in high concentrations contributes to shelf-life in hard candy and crystallised coatings.

- Maltitol and xylitol can support shelf stability in sugar-free products while resisting moisture uptake.

- Using the right sugar or sugar blend also helps inhibit microbial growth – crucial in high-moisture fillings or jams.

Equipment and Automation: Merging Craft with Control

Confectionery production has always required a balance of precision and creativity – and nowhere is that more visible than on the factory floor. Whether you’re producing chewy jellies, glossy coatings, or aerated marshmallows, the choice of equipment directly affects product quality, consistency, and efficiency.

Traditional systems like cookers, depositors, extruders, and cooling tunnels remain at the heart of most confectionery lines.

But the industry is rapidly evolving. Modernisation trends such as robotic arms, inline quality control (QC), and digital traceability systems are transforming confectionery manufacturing into a smart, data-driven process. These tools reduce waste, improve safety, and support faster changeovers between SKUs – critical in responding to consumer demand for limited-edition and functional formats.

1. Cookers & Kettles

- Used for dissolving sugar and heating mixtures to precise temperatures.

- Types include batch cookers, vacuum cookers, and continuous cookers.

2. Depositors

- Precisely portion and deposit mixtures into moulds (eg, for gummies, jellies, caramels).

- Can be piston-type or servo-controlled for high-speed accuracy.

3. Extruders

- Shape chewy, aerated, or layered confections (eg, liquorice, nougat bars).

- Often paired with cooling systems for immediate setting.

4. Cooling Tunnels

- Rapidly cool down products to set structure, prevent sticking, and prepare for packaging.

- Essential for chocolate enrobing, gummies, and marshmallow products.

5. Enrobers

- Coat products with chocolate or compound coatings.

- Paired with cooling tunnels to set the coating.

6. Moulding Lines

- For chocolate and sugar confectionery shaped in specific moulds.

- Includes vibrating, cooling, and demoulding stations.

7. Aeration Systems

- Used for products like marshmallow and nougat.

- Incorporate air to create light texture.

8. Mixing and Blending Equipment

- High-shear mixers or planetary mixers ensure homogeneity in fondants, pastes, or fillings.

- Vacuum mixers can remove unwanted air for smooth texture.

9. Sugar Grinders & Refiners

- For creating confectioner’s (icing) sugar or adjusting granulation.

- Can be part of inline systems to prep sweetener forms.

Modern Automation & Control Systems

1. Robotics and Automation

- Robotic arms for packaging, palletising, or delicate handling.

- Reduces manual labour and improves hygiene.

2. Inline Quality Control Systems

- Cameras, sensors, and weighing systems for detecting shape, weight, or colour deviations.

- Ensures consistent output and reduces waste.

3. CIP (Clean-in-Place) Systems

- Automated cleaning for pipes, tanks, and mixers.

- Crucial for allergen control and GMP compliance.

4. Digital Process Control / SCADA Systems

- Centralised systems for monitoring batch parameters, temperature, mixing times.

- Data capture for traceability and recipe control.

If you’re targeting clean label or functional confectionery markets, automation also supports:

Small-batch capability: Ideal for innovation labs and formulation R&D. With growing interest in clean label and allergen-free formulations, automation also plays a vital role in sanitation and segregation. Machines designed for easy cleaning and allergen control help manufacturers meet labelling claims while maintaining production efficiency.

Hygienic design: Stainless steel, easy-clean systems for allergen control.

Precision dosing: Important for sugar reduction and active ingredient delivery.

From traditional copper pans to cutting-edge robotics, equipment choices shape not only how confectionery is made – but how reliably and responsibly it reaches the shelf.

Formulation Challenges

Confectionery manufacturers face a balancing act: delighting consumers with indulgent texture and flavour while meeting rising expectations for health, ethics, and shelf-life. Reformulating for today’s market isn’t just about swapping sugars – it means rethinking ingredients, processes, and packaging together.

Sugar Reduction Without Sacrificing Quality

Reducing sugar impacts sweetness, yes – but also affects bulking, texture, and water activity. Formulators can blend functional fibres like inulin or FOS with natural sweeteners, or use sugar alcohols and starch-based alternatives to maintain mouthfeel, viscosity, and shelf-life.

Vegan and Allergen-Free Innovation

Demand is rising for plant-based and allergen-free confectionery. Gelatine-free gummies (using pectin or modified starches), dairy-free fillings, and egg-free foams require a deep understanding of texture agents, gelling behaviour, and stabilisers that can replace animal-derived ingredients without compromising structure.

Shelf-Life and Textural Stability

Soft or filled confectionery, like marshmallows, truffles, or caramels, need tailored sugar systems that balance hygroscopicity, crystallisation behaviour, and microbial stability. Choosing the right sugar or sugar blend (e.g. glucose syrup for chewiness or invert sugar for water retention) extends freshness over long storage.

Packaging and Moisture Control

As sugar systems shift, so must packaging strategies. Materials need to guard against moisture migration and oxidation while preserving the texture of sugar-reduced or soft-centred products. Multilayer films, MAP (Modified Atmosphere Packaging), or barrier coatings are increasingly used to lock in product integrity.

HFSS Regulations and the Impact on Formulation

Confectionery manufacturing is increasingly shaped by complex formulation challenges that go far beyond sweetness alone. Reducing sugar without compromising texture, flavour release, shelf life, or visual appeal remains one of the industry’s biggest technical hurdles, as sugars play a structural role in crystallisation, moisture control, and mouthfeel. These challenges are now amplified by HFSS regulations, which place additional pressure on manufacturers to reformulate products to meet sugar thresholds while still delivering indulgent experiences consumers expect.

Clean Label Considerations in Confectionery

The clean label movement is reshaping the confectionery landscape. Today’s consumers – especially parents and health-conscious snackers – want ingredient lists that are short, recognisable, and free from E-numbers and artificial additives. For manufacturers, this means rethinking not just flavours and colours, but also sweeteners and texturising systems.

To support clean-label claims while maintaining the sensory and structural qualities of traditional confections, formulators are turning to:

- Invert sugar (a natural blend of fructose and glucose) for soft, stable textures in jellies and fillings

- Natural syrups like honey or agave to replace synthetic sugars while adding depth of flavour

- Plant fibres such as inulin or fructooligosaccharides (FOS) to reduce sugar content, support gut health claims, and enhance mouthfeel

Critically, the choice of sweetener doesn’t just affect label appeal, it influences technical parameters like crystallisation behaviour, water activity, and microbial stability, which in turn impact product longevity and quality.

As the sector moves toward more transparent formulations, ingredient selection must deliver on performance, perception, and preservation.

Shelf Life and Storage Stability

In confectionery manufacturing, shelf life is influenced as much by formulation as it is by packaging. The sugars chosen – fructose, glucose, sucrose – play a direct role in how products hold up over time in terms of texture, safety, and sensory appeal.

Crystallisation control is especially critical. Fructose and glucose, particularly in syrup form, act as anti-crystallisation agents, making them ideal for soft caramels, jams, fillings, and frozen desserts. In contrast, sucrose readily crystallises, which is useful in brittle candies or fudge but a liability in smooth-textured confectionery unless properly managed.

Water activity (aw) is another major factor. Lowering water activity with sugars like fructose or invert sugar can inhibit microbial growth and extend the stability of high-moisture items like fruit gels or filled chocolates. The hygroscopic nature of fructose also helps retain moisture in chewy or ambient-stable snacks.

Textural longevity is vital in modern confectionery where shelf life may extend for months. Fructose’s moisture-retention properties help maintain chew in snack bars and gummies. Meanwhile, glucose and sucrose systems—especially when optimised with other functional ingredients—support consistent bite and structural integrity.

Dextrose Equivalent (DE) helps formulators fine-tune carbohydratefunctionality. A higher DE indicates more simple sugars, yielding a sweeter, more reactive syrup that dissolves easily and browns faster. This is especially useful for adjusting solubility and sweetness in baked or cooked confections.

Confectioners must balance all of these elements—crystallisation, moisture, microbial safety, and textural integrity—to create products that are both indulgent and shelf-stable.

Regulatory and Safety Considerations

Confectionery manufacturers must navigate a complex and evolving regulatory landscape to ensure both consumer safety and brand credibility. Compliance isn’t just a legal requirement, it’s foundational to maintaining trust and operational consistency in domestic and export markets.

Allergen Controls

With the rise in dietary sensitivities and food allergies, producers must rigorously manage potential cross-contamination risks. This includes producing nut-free, gelatine-free, and dairy-free confections in dedicated environments, using allergen-safe alternatives such as pectin, agar, or starch-based gelling agents.

Labelling Requirements

UK and EU food labelling laws demand transparent declaration of nutritional content, sweetener types, and GMO status. For instance:

- Any use of genetically modified ingredients must be clearly disclosed.

- Sweeteners like sorbitol, xylitol, or stevia must be labelled in accordance with their E-numbers or functional names.

- “Reduced sugar” or “no added sugar” claims must meet strict threshold criteria.

Production Standards

All confectionery facilities must follow HACCP (Hazard Analysis and Critical Control Points) principles, alongside Good Manufacturing Practices (GMP) to manage safety hazards across production. In sweetener handling and sourcing, ingredient traceability and supplier documentation are vital, particularly for sugars derived from GMO crops or imports from regions with varying quality standards.

From ingredient sourcing to packaging labelling, regulatory compliance is a non-negotiable pillar of successful confectionery manufacturing.

Conclusion: Formulating for Flavour, Function, and Future-Proofing

Modern confectionery manufacturing is about more than delivering indulgence – it’s a technically sophisticated balancing act. From clean-label requirements to extended shelf life and allergen-free alternatives, formulators must weigh functional performance, regulatory compliance, and consumer trends in every decision.

Sugars remain a cornerstone of this process—not just for sweetness, but for their critical role in structure, texture, preservation, and sensory experience.

At Lehmann Ingredients, we work closely with manufacturers to select the right sweetener systems—from traditional sucrose to glucose syrups, invert sugars, or functional starch blends. Whether you’re reformulating for sugar reduction, looking to improve shelf-life, or exploring novel textures, we can help you stay ahead of the curve—and your competition.

Request a Sample

FAQs: Confectionery Manufacturing & Sweetener Functionality

The most common are sucrose, glucose syrup, fructose (including crystalline fructose), and invert sugar; each offering unique benefits for sweetness, texture, crystallisation, and shelf-life.

Fructose improves chewiness and moisture retention, glucose enhances softness and browning, and sucrose contributes to crispness and structure through crystallisation.

Glucose syrup prevents crystallisation, enhances smoothness, and supports moisture control; ideal for fudges, fondants, jellies, and frozen desserts.

Sucrose remains a go-to ingredient due to its clean flavour, balanced sweetness, and predictable crystallisation; especially in traditional applications like brittles and hard candies.

DE measures the degree of starch hydrolysis; higher DE means sweeter, more soluble, and more reactive syrups. Choosing the right DE helps optimise texture, browning, and shelf stability.

Manufacturers can replace artificial sweeteners with natural options like agave or honey, use invert sugar for soft texture, and reduce E-numbers with plant-based colours and fibres like inulin or FOS.

No. HFCS is largely avoided in the UK due to public scepticism around GMOs. UK regulations require GM-containing products to be clearly labelled, making HFCS less attractive for brand positioning.

Sugar reduction without losing structure, vegan/gelatin-free formats, allergen avoidance, and ensuring shelf stability in high-moisture products.

Sugars like fructose and glucose lower water activity more effectively than sucrose, improving microbial resistance. Syrup forms also help prevent crystallisation and maintain textural consistency.