Sugar esters, also known as sucrose fatty acid esters, are emulsifiers made from sucrose and plant-derived fatty acids. This creates molecules with both water-loving and fat-loving properties, allowing them to stabilise emulsions, control viscosity, and improve texture across a wide range of applications .

Our Sucrose Ester of Fatty Acids offer precise, high-performance emulsification for demanding food systems where standard emulsifiers fall short.

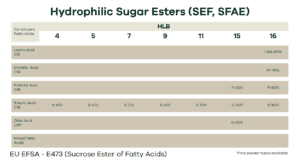

With multiple hydrophilic–lipophilic balance (HLB) options available, our sugar esters allow formulators to fine-tune functionality, improve processability, and achieve consistent results in both traditional and modern formulations.

Sucrose Esters are highly versatile and used across a broad range of food categories, particularly where stability, flow, and surface control are critical.

Typical applications include:

Sugar confectionery (gummies, hard candy, caramel, chewing gum)

Chocolate confectionary, such as decorations, coatings and fillings

Milk-based and dairy alternatives (such as almond, coconut, oat milk)

Fine baked goods such as biscuits, cakes and cereal bars

Dairy applications including ice cream, whipping cream and aerated systems

Fillings, spreads, and bake-stable applications

Powdered products and protein systems

Key functionalities include:

Emulsion stabilisation (water / oil control)

Viscosity reduction in heated systems

Control of starch gelatinisation and retrogradation

Defoaming in heating

Improved mechanical resistance

Anti-stick and anti-clumping performance

Control of crystallisation

Improved flow, coating, and enrobing behaviour

Shape retention and overrun control in creams and foams

We offer a broad range of sucrose fatty acid esters with carefully controlled HLB values to suit different formulation needs.

Sugar esters are used at low levels (typical inclusion levels of 0.03–0.5%) and contribute minimal nutritional impact to finished products.

Availability and regulatory status may vary by grade and region, and our technical team can advise on the most suitable option for your application. Full nutritional and regulatory information is available on request, depending on grade and market.

Sugar esters are multifunctional ingredients with a unique balance of hydrophilic and lipophilic properties.

Key properties:

Derived from sucrose and vegetable fatty acids

Adjustable HLB range for precise emulsification control

Heat-stable and process-tolerant

Effective at low inclusion levels

Compatible with a wide range of fats, sugars, and proteins

Neutral flavour and colour impact in finished products

Our team is here to help you find the emulsifying solution you need. Get in touch to discuss your application or request technical guidance.